State of the Art Ii Permanent Strain Response of Unbound Aggregates

- Domicile

- Courses

- Laboratory

- Publications

- Presentations

- Research Projects

- Professional and Service

- Student Advising

- Synergistic Activities

- Technical Reports

EQUIPMENT AND FACILITIES

ASU is a earth-form academy with state-of-the-fine art facilities for education and enquiry. The School of Sustainable Engineering and the Built Environment is located on the main campus, virtually x minutes from the Heaven Harbor International Airport. Facilities are available that will provide ample infinite and equipment for the conduct of research.

Advanced Pavements Laboratory

The Advanced Pavements Laboratory (APL) at ASU is a state-of-the-art facility that provides full capability for characterizing asphalt concrete mixtures, unbound materials, and consummate asphalt binder characterization. The APL is considered one of the best and most advanced laboratories in the United states of america. The APL occupies more than 4000 square anxiety in the Interdisciplinary Scientific discipline and Engineering Edifice Two. The entire testing laboratory comprises of four main sections depending upon the specific functionality. The APL is fully equipped with ovens, scales, mixers, Marshall Mix design molds, water baths and compactors. A pinch automobile for concrete cylinders and a vibratory compacter for unbound materials are also available. An adjacent area to the laboratory is defended for aggregate storage and treatment. This includes sieving and batching of aggregates for preparing asphalt mixtures. The surface area is likewise equipped with state-of-the-fine art automated coring machine, and two saws for preparing various sizes and geometry of test specimens.

Folder Laboratory : This department of the laboratory has country-of-the-art equipment for asphalt binder testing and characterization. The primary equipment includes Superpave Rotational Viscometer, Bending Beam Rheometer (BBR), Dynamic Shear Rheometer (DSR), Rolling Thin Flick Oven (RTFO), and Pressure level Aging Vessel (PAV).

Mixing Laboratory : Asphalt sample preparation is carried out using an SHRP approved procedure using a Superpave Gyratory compactor. The laboratory has two Troxler and i IPC Servopac compactors. Four large ovens for controlling the mixing, aging, and compaction temperatures are available inside this laboratory, too every bit specific gravity apparatus for density measurements of fabricated specimens. A Troxler ignition oven is besides available in this section.

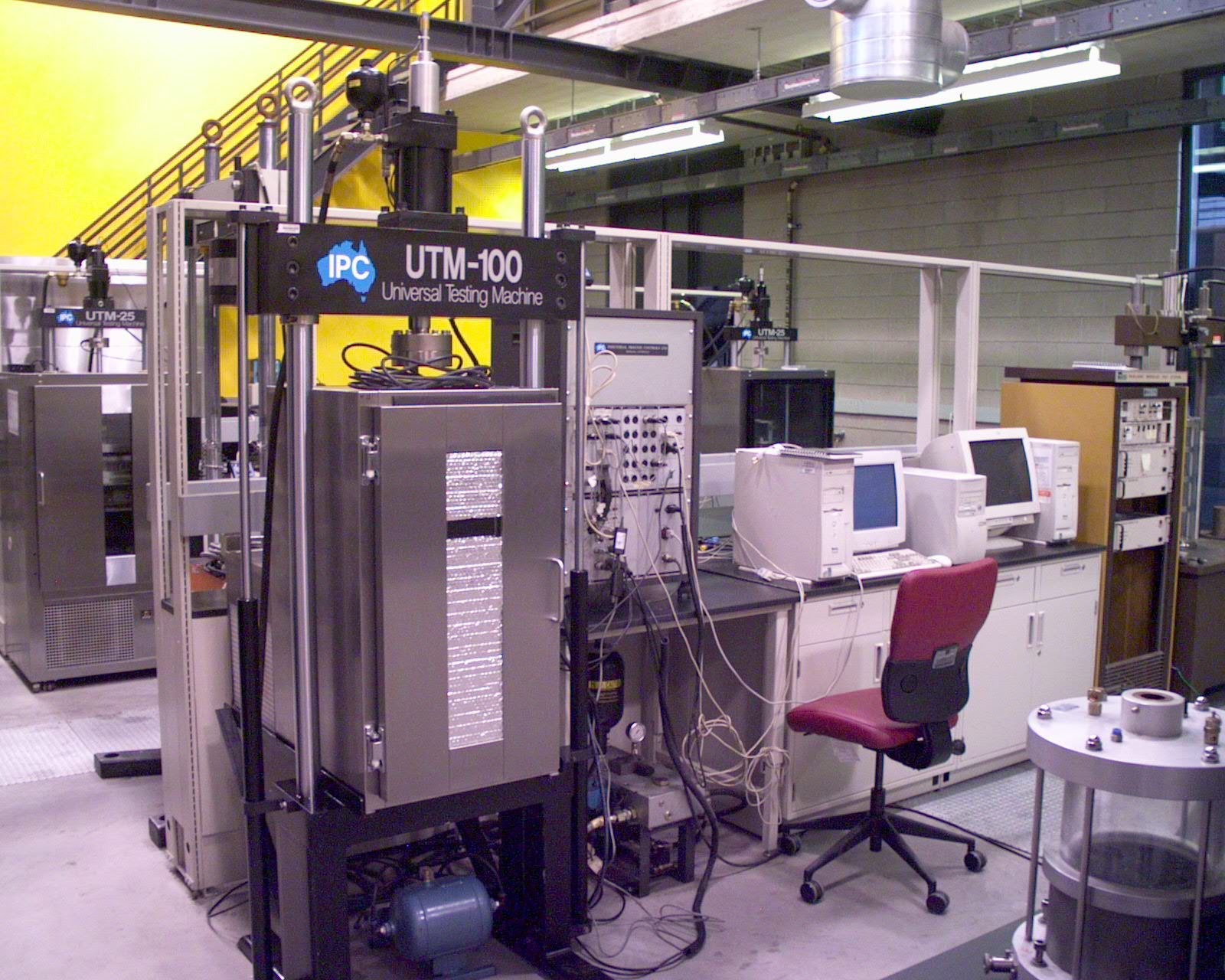

Advanced Material Testing Laboratory : This is the master research laboratory for advanced material characterization testing of asphalt mixtures and unbound materials. Several state of the art servo-hydraulic closed loop systems are housed in this section of the laboratory. These include two 25 kN and one 100 kN Universal Testing machine (Industrial Process Command � IPC) for uniaxial and triaxial testing of paving materials. All these 3 systems accept environmental chambers for temperature conditioning. In improver, an Instron system dedicated for Indirect Tensile testing and an SBEL system that has triaxial capabilities for unbound material are also bachelor inside this section.

2 beam fatigue appliance for fatigue life evaluation of asphalt mixtures are also available. Each beam fatigue appliance is a stand up-alone system with environmental chamber and information conquering software that performs the SHRP designated M009 test protocols. The test tin can be run either in strain or stress controlled loadings.

All machines accept digital servo-controlled actuators with integrated command and data acquisition systems to provide accurate force or deportation waveform generation. All of the machines are equipped with customized information acquisition software that provides a user-friendly interface with the system to bear out a wide range of tests and analysis procedures. Some of the tests that are run on asphalt concrete on a routine basis include:

Dynamic Complex Modulus

Resilient / Elastic Modulus � Compression and tension

Strength � Compressive and tensile

Repeated Load Permanent Deformation

Static Creep / Menstruum Fourth dimension

Work / Energy � Compressive and tensile loading

Indirect Tensile Strength, Pitter-patter and Fatigue

Beam Flexural Stiffness / Fatigue

Poisson�southward Ratio evaluation

Rapid Triaxial Test for Rutting Evaluation

CoreLok device to mensurate specific gravity and air voids of samples

The figures below show some of the equipment available at the APL.

APL Laboratory

HMA Mixture Preparation Area.

Material Testing Systems.

Textile Testing Systems.

Specimen training equipment.

Cloth characterization test equipment.

Thermal Label Lab

At the National Center of Excellence for SMART Innovations.

Location

Integrated Science and Technology Building 2

Phone: (480) 727-9124 Fax: (480) 965-8087

Web Site: http://ncesmart.asu.edu

The Thermal Storage and Radiative Characterization laboratory is part of the EPA designated National Heart of Excellence for SMART Innovations. 1 focus area in this laboratory is dedicated to better understand how paving materials interact with the urban climate and contribute to surface and subsurface temperature fluctuations. Laboratory thermal backdrop tests are conducted in addition to field instrumentation and experiments. The information are used to model the pavement heat absorption and transfer, and evaluating impact on energy and safety.

Go dorsum to home folio.

Source: https://www.public.asu.edu/~kaloush/Laboratory.htm

0 Response to "State of the Art Ii Permanent Strain Response of Unbound Aggregates"

Postar um comentário